Many factors come into play when comparing the material properties of thermoplastics found in injection moulding versus “thermoplastic-like” materials used in an industrial-grade 3D printing technology like stereolithlography (SL).

SL uses a thermoset liquid, not a thermoplastic, which is UV-cured in layers to form final parts. Because of this major difference in fabrication methods, material properties like tensile strength, heat deflection and flexure modulus may differ from SL’s more traditional counterpart. Furthermore, SL produces anisotropic properties where the values for X, Y, and Z axis may differ depending on the orientation of the build—a consideration unique to 3D printing processes.

At Protolabs, a thorough selection of thermoplastic-like materials are offered through SL, but what may surprise you is the versatility and range of potential applications for SL parts. We’ll take you through each material and its properties, and compare them with one another (as well as with moulded plastics) to help you decide how to best implement SL.

Chart 1: One PC-like material and moulded PC thermoplastic are compared across six material property categories. Notice how the heat deflection in the PC-like parts are be much lower or have a wider range than the moulded PC due to the anisotropic properties discussed earlier. *Heat deflection was measured at 66 psi.

Polycarbonate-Like Materials

Accura 5530 material is transparent in colour, temperature tolerant and water resistant. It also is resistant to automotive fluids making it suitable for under-the-hood and electrical applications. Note that secondary operations are required to achieve transparency and the final part will still retain a slight amber hue.

Somos NanoTool has an added ceramic filler that increases stiffness and brittleness over other SL materials. Along with stiffness, Nanotool touts the highest temperature resistance compared to most materials offered in SL. It’s regularly used in aerospace and automotive applications that often require greater strength and temperature resistances.

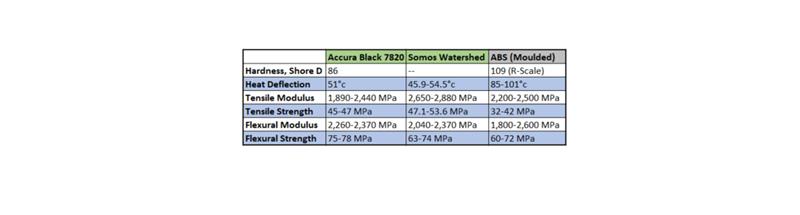

Chart 2: Four ABS-like materials and moulded ABS thermoplastic are compared across six material property categories.

ABS-Like Materials

Accura Black 7820 has high strength and good dimensional stability, even in high humidity. The material is black and commonly used in automotive parts, consumer packaging, electrical housings and toys due to its impact resistance and ease of secondary finishing that provides the appearance of production quality.

Somos Watershed XC 11122 is strong, durable, water-resistant ABS-like material. It’s nearly colourless and mimics a clear engineered-grade plastic. Watershed’s high clarity makes it a perfect material for prototyping lenses, flow-visualisation models and micro-fluidic parts. Note that secondary operations will be required to get the material completely clear. Watershed will also retain a very light blue hue afterward.

Chart 3: Two PP-like materials and moulded PP thermoplastic are compared across six material property categories. Notice that properties are fairly similar between each.

Polypropylene-Like Materials

Accura Xtreme White 200 is comparable to both a polypropylene (PP) and ABS thermoplastic in that it offers strength and durability, lending itself well to application that require snap-fit features. Note that Xtreme White 200 has the lowest heat deflection of the SL materials offered at Protolabs.

Accura Xtreme offers a PP-like material that provides good toughness and durability where snap fits are required. This material is grey in colour and you would find this in assemblies or in demanding applications.

Parting Notes

Unlike thermoplastics, long-term exposure to UV light and moisture will alter the appearance and mechanical properties of SL materials if they are not protected by plating or painting. Over time, you may experience part warpage, yellowing and brittleness in some parts. SL parts are not intended for long-term use in many instances, but understanding the short-term benefits of having highly cosmetic and functional parts to use during early prototyping can greatly benefit you.

Remember to work closely with the 3D printing experts to ensure that build orientation, anisotropism and material properties are optimised. Adjusting the direction in which the part is built can often improve the material properties and clarity of the part.

Click here to read more design tips on creating plastic and metal parts for 3D printing, CNC machining, and injection moulding processes.