At Protolabs, we use automation software to quote parts and highlight features that need design consideration based on a process developed around producing parts rapidly. The software will catch features that are unmanufacturable up front (or manufacturable, but with additional tools and equipment), but it will also highlight areas that do not necessarily require change, but can improve the design's overall machinability; corner pockets, engraved text, thin walls, deep pockets and holes, and complex geometries.

Here are tips to help you design more cost-effective machined parts.

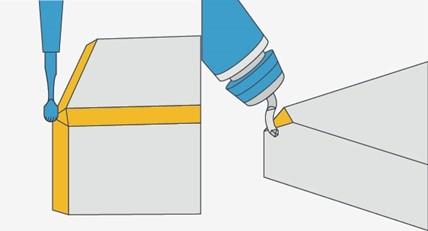

Here’s an example of adding reliefs to sharp corners— in this case a stainless steel box that holds a collection of baseball cards—which helps achieve the perfectly square corners needed to fit the cards.

1. Provide relief to corner pockets

Consider the corners of a machined pocket—the inside of an electronics housing, perhaps, or a bracket used to capture the body of a rectangular component. One common design oversight is leaving the intersection of the vertical walls on those part features perfectly sharp. To illustrate, think about machining a stainless steel box to hold a deck of cards. The only way to get the perfectly square vertical corners needed to fit the cards, is with electrical discharge machining (EDM), or, multiple flat plates bolted together. Both can be slow and expensive processes.

Instead, we'll equip one of our machining centres with the smallest end mill available to clean out the corners. In 304 stainless steel, that means a 0.031 in. (0.8mm) end mill, which leaves a corner radius of 0.016 in. (0.4mm). That's pretty sharp, but the depth is limited. The length of most steel-cutting end mills in this size range maxes out at five times the cutter diameter. Machining with small end mills such as this is also slow and delicate work, driving up the cost of your project because of added milling time.

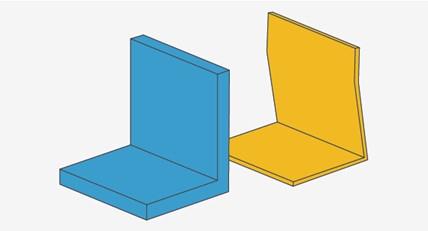

In an attempt to remove burrs and break sharp corners, designers will often smooth external part intersections with chamfers or corner radii, as seen in the illustrations here.

A more budget-friendly approach is machining a relief in each corner of the pocket. This removes that pesky radius, leaving a U- or C-shaped clearance instead. It also allows for far deeper pockets—by cutting a 0.25 in. (6.35mm) wide relief in each corner, functionally sharp corners to around 1-1/4 in. (32mm) in depth are possible. And by switching to aluminium or even plastic, pocket depths twice that of steel are possible. Best of all, designing pockets in this manner reduces part cost, since larger end mills can be used and material removal rates increased accordingly.

2. Deburr Edges Yourself

Avoiding corner breaks is another radius-related, cost-cutting measure. In an attempt to remove burrs and break sharp corners, designers will often smooth external part intersections with chamfers or corner radii. It's understandable, and sometimes quite necessary, but it can also be expensive. With metal parts, Protolabs provides an automated deburring option, and plastics are delivered as-machined or with sharp edges per the illustration. If the part design calls for an edge break, we have to call up an additional tool (a ball end mill) and machine these corners using a 3D profiling motion. We generally run these tools at a high rpm, and small amounts of material are removed, but it's still a lengthy process to go back and forth until each corner is smooth. Many customers opt to save a few bucks by deburring these parts on their own with a file, some abrasive paper or a buffing wheel.

3. Avoid Text Until Moulding

Similarly, text engraving is an aesthetically pleasing but time-intensive operation, one that might be best to avoid if possible. Here again, a ball end mill is used to trace whatever letters, numbers, and symbols are called for on the CAD model. It looks great, and might be a valid requirement on your machined part, but is probably more appropriate on injection-moulded parts, where additional machining time is amortized over higher part volumes. Because of our toolsets for metals vs. plastics, we have a minimum feature size of 0.035in (0.90mm) in metals and 0.020in (0.51mm) in plastic.

Small tool diameters add machining time so consider removing text or logos from machined prototypes.

4. Be Cautious of Thin Walls and Features

Our standard part tolerance is +/- 0.005 in. (0.13mm). If you have a feature that is 0.020 in. (0.51mm) or smaller, our automated quoting system will highlight it as a thin-wall geometry, but keep in mind that we'll still allow it to be machined, so the machined part may differ slightly from your original design. Any thin walls that are 0.020 in. or less are not only subject to breakage during the machining operation, but may flex or warp afterwards. Beef them up as much as your part design allows.

Use caution with thin-walled parts because they are subject to breakage during the machining operation or may flex or warp afterwards. Beef them up as much as your part design allows.

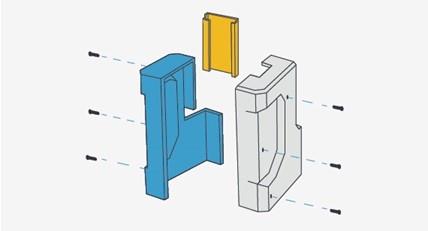

5. Keep it Simple

Very deep pockets are a no-no, even if the corners are relieved. Not only does it take a lot of machining time to remove all that material, but any residual stress in the raw material tends to show its ugly face as pockets get deeper and walls taller. Gussets or support structures might be used to support these workpieces and prevent movement due to stress, but these tend to increase machining costs. Keep it simple is the best advice for any manufacturer or product designer of machined parts.

Keep things simple. If the design gets too complex, consider breaking it into multiple components that can be bolted or screwed together.

The same principle applies to overall part geometry as well. Don't attempt to make parts do more than they should. Maximizing material usage may create work holding or machining problems, in turn increasing costs. If the design gets too complex, consider breaking it into multiple components and using fasteners to assemble them. No one likes assembly costs, or the complexity that goes with multiple pieces, but it might be the best approach for difficult-to-machine parts if speed is one of your requirements. Sculptured surfaces, cavernous slots (think heatsinks), super deep holes (hydraulic manifolds), and threads—these are some of the common machining cost drivers that can chip away at your project budget.

6. Explore Alternative Materials

One of the simplest ways to stay within budget, assuming it meets your requirement, is by switching to a more machine-friendly or less expensive material. Our material selection includes a range of metals and plastics, each with its own engineering attributes, aesthetics, machining considerations, and material cost. Here are some key material considerations:

- 17-4 PH stainless steel is difficult to cut. If high strength and corrosion resistance isn't critical, try 316L or 304 instead.

- Copper is a great electrical conductor, but it's far more expensive than aluminium. While aluminium is roughly 60 percent of the electrical conductivity of copper, the weight and cost savings may drive you to reconsider aluminium.

- If hardness is a concern, 4140 might be your first choice, but 1018 is very low cost and takes an admirable case hardening.

- One sure way to make a machinist smile is to give him or her an order for some brass parts, a soft metal that's easy to mill and might just have the mechanical, chemical, or conductive properties needed for your application.

- On the plastics side, we have nearly three dozen to choose from. All of them are relatively easy to cut, a factor that often—but not always—equates to lower cost parts. Some plastics offer superior wear, corrosion, or chemical resistance, others perform well under heat or flame, while still others offer excellent strength, impact, or electrical properties. Typically, the softer the material, the more risk for dimensional stability and stringing when milling.

Not sure which material to consider? Please feel free to check out the complete material list or call one of our applications engineers for advice.

When you upload a CAD model to our website, our quoting tool calculates what can be machined within our capabilities, and what has risk. Its conclusions are clearly spelled out in the quote, giving you a chance to adjust the part design if so desired and spin the quoting wheel again. If you're ever in doubt, however, contact our applications engineers at or customerservice@protolabs.co.uk