It seems there’s some truth to the Goldilocks story, at least when it comes to plastic injection-moulded part design. That’s because several potential problems related to feature thickness exist, some of which can be avoided by shooting for a “just right” dimensional value, and others by optimising your design for machinability by a specific set of tools (or endmills) used to machine your mould cavity.

All parts submitted to our advanced quoting system get DFM (design for manufacturing) feedback and advisories, but what if some of those advisories require some remedial design work? No worries! Those advisories provide the info you need to create high quality parts with us, quickly and accurately. This design tip offers up details on some of the most common advisories and helps you move forward before your mould is made and production begins.

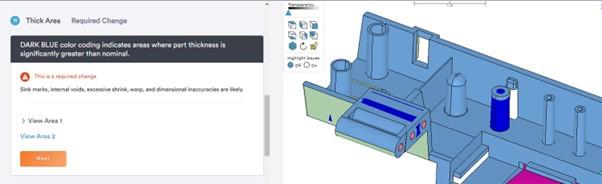

Required change: Thick Area

Sink marks, internal voids, excessive shrink, warp, and dimensional inaccuracies are likely.

Before diving into the nitty gritty, let’s discuss some quick review around nominal thickness of your part design, and what affects that might have on the final moulded part. As noted above, improper wall thickness can lead to a host of problems. Very thick parts will lead to cosmetic and structural problems like voids and warp, while very thin parts may reduce structural strength, or not fill at all. You certainly don’t want that, but even more importantly, walls that are too thick or too thin will make the part un-mouldable. As a best practice, it is always critical to design your part for the recommended wall thickness of the material and maintain a consistent wall thickness throughout your part.

Recommended Wall Thickness by Plastic Type

| MATERIAL | RECOMMENDED WALL THICKNESS |

| ABS | 1.143-3.556mm |

| Acetal | 0.762-3.048mm |

| Acrylic | 0.635-12.7mm |

| Liquid crystal polymer | 0.762-3.048mm |

| Long-fibre reinforced plastics | 1.905-25.4mm |

| Nylon | 0.762-2.921mm |

| Polycarbonate | 1.016-3.81mm |

| Polyester | 0.635-3.175mm |

| Polyethylene | 0.762-5.08mm |

| Polyphenylene sulfide | 0.508-4.572mm |

| Polypropylene | 0.635-3.81mm |

| Polystyrene | 0.889-3.81mm |

| Polyurethane | 2.032-19.05mm |

Now on to the fun stuff: machinability. We use a proprietary, automated process to manufacture our moulds to accelerate the process. We use standardisation and machine connectivity from the time that you upload your part, to the time that the finished part leaves our facility. Standardisation drives our speed, but it does come with a trade-off for product developers optimising a part for our process: Sometimes we can’t machine your part exactly as you designed it. Here are the common machinability advisories, as well as resolution strategies to ensure that your part design is manufacturable, and you get it fast.

Draft Suggestion

The areas indicated show faces with insufficient draft. We suggest a minimum of 1 degree draft in order to avoid possible cosmetic defects during milling and ejection.

Draft is a fundamental element of DFM, and if you’re not familiar with the concept, you can come up to speed quickly with this design tip. In this case, the required change is likely driven by one of two things:

- EJECTION: Vertical walls that are not drafted will generally increase retention against the geometry forming feature in the mould. This means it will be really had to eject the part without creating scratches and scuffs known as “drag marks.” Worse yet, the increased retention could make the part stick into the mould, and bend or break ejector pins. For this reason, it is always best practice to include AT LEAST 0.5 degrees of draft on all vertical faces. In this example, however, we have another challenge.

- MACHINABILITY: The “faces with arrows” described in the required change are located on a deep boss and are all at roughly the same depth. This is a good indicator that the features can be machined but would require additional draft or thickness—not to facilitate ejection—but rather to ensure that we can fit an endmill into the feature to mill it fully.

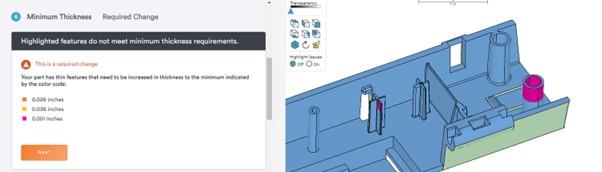

Required Change: Minimum Thickness

Your part has thin features that need to be increased in thickness to the minimum indicated by the colour code.

Earlier, we talked about how some required changes are driven by the thickness needed to maintain machinability. In this case, the BLUE wall faces are less than 0.508mm in thickness. To machine this feature, we need to use our smallest endmill. The thinnest feature that we’re able machine is 0.508mm, so to resolve this change, you would need to increase the thickness to 1.29mm on the boss whilst maintaining any draft you already have on the feature. More on this below.

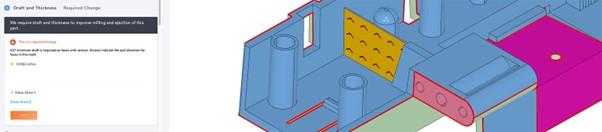

Required Change: Draft and Thickness

0.5° minimum draft is required on faces with arrows. Arrows indicate the pull direction for faces in the mould.

Unsurprisingly, draft and thickness are exactly what you think. If you recall our tip on types of endmills, many of them require draft in order to mill a feature of a certain depth. In the case of a draft and thickness requirement, the feature thickness must be increased to fit the tool diameter required to mill it, but the vertical faces on the feature must also be drafted to facilitate the draft angle of the cutter. These required changes are most common on features that are both thin and deep.

One thing to note: We do have some flexibility when it comes to required changes for draft and thickness. Specifically, we can reduce the draft needed in exchange for a higher thickness requirement, and vice versa, there could also be other solutions to overcome this requirement by the use of mould inserts. Review those possibilities with one of our applications engineers to see if your part would qualify.

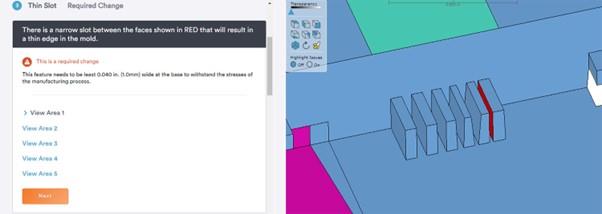

Required Change: Thin Slot

This feature needs to be at least 1.0mm wide at the base to withstand the stresses of the manufacturing process.

Thin slots are blade-like pieces of milled aluminium in the mould required to form slotted features in a part. It is important to remember that the mould cavity is the exact inverse of the geometry on your part. So, a thin slot or channel in the part geometry will require a thin piece of aluminium in the mould, often standing on its own, unsupported. This becomes a challenge due to the stresses of the manufacturing process itself. Think of a piece of aluminium roughly similar to the blade of a butter knife. Now imagine adding up to 96.5MPa (14,000 psi) of pressure to that blade. Do you think it would flex, bend, or break? This is the same premise that we’re up against when moulding with thin slots. The freestanding blade-like aluminium is prone to deflection (flexing and bending) and in some cases even breaking off completely, which means we need to either modify and repair the tool with increased thicknesses and in worst case scenarios have a new half or full tool made.

Resolving this required change is easy. Simply increase the slot width of the feature, thus increasing the thickness of the aluminium that will form it in the mould.

Navigating Thin Slots in Moulding Design

| Slot Min | Ratio @ 0° | Ratio @ 0.5° | Ratio @ 1-2° | Ratio @ 2°+ |

| 0-0.254mm | 1:1 | 1:1 | 2:1 | 4:1 |

| 0.254-0.508mm | 1:1 | 2:1 | 4:1 | 8:1 |

| 0.508-0.762mm | 2:1 | 4:1 | 5:1 | 10:1 |

| 0.762-1.016mm | 2:1 | 5:1 | 8:1 | 15:1 |

| 1.016-1.524mm | 4:1 | 8:1 | 10:1 | 20-1 |

| 1.524mm + | 5:1 | 10:1 | 15:1 | 25-1 |

Note: Double all ratios if captured on three sides

Remember, required changes and moulding advisories are a critical step to making your part mouldable. Hopefully these tips on some of the most common ones will help guide you past them and keep your parts on schedule. If you have any questions, don’t hesitate to contact our applications engineers for help at +44 (0) 1952 683047 or customerservice@protolabs.co.uk.