Starting at the very beginning, get your part quoted using a company that has design for manufacturability software. That way, you can almost instantly know whether your part is manufacturable. If it is, great, go ahead and produce your part; if not, try again, or if you are struggling to get to a manufacturable stage and the company has a consultative service, call them up and solve the issues with the support of an applications engineer, as they say, two heads are better than one.

But wait, if you want to produce a part with speed in mind, we need to take a step back! We need to consider things such as the service we will use, whether the part will be filled, will have supports, how it will be oriented etc.

Let’s start at the beginning, designing your part.

To fill, or not to fill

Do you need to consider filling your part? Remember, when it comes to 3D printed parts, the ratio between the inner structure and wall thickness is important; if you don’t get it right, your part may not be suitable for application.

If your ratio is good and your part can go hollow, fantastic, that will be quicker. But if not, there are still ways around this; the part does not need to be filled solidly. There are lots of different ways to fill a part. The honeycomb structure is one of the quickest and strongest methods you can select. Or the rectilinear structure, which is massively popular and can reduce speeds by up to a quarter.

Split or stick

Sometimes splitting your part into several smaller parts that can be assembled post-process can speed up your part’s production. If you can produce these parts all in one build, the process would still be quicker. Of course, to do this, the parts would need to fit into the maximum size limitations that your supplier offers.

Do you need supports?

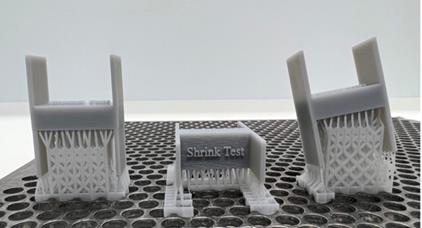

Supports are sometimes necessary; unfortunately, they will add production time to your print job. Supports will be needed if you have overhangs at more than 45° angles, although we often recommend keeping angles to less than 30° to avoid issues, especially if you are using thin, high walls. If there is a way for you to avoid tall, thin walls, large hollow areas or wider angles, then you will save yourself a lot of time.

Portrait vs. Landscape

If you use Protolabs, we recommend you leave part orientation to us. We will ensure that the most cost-effective, efficient positioning is selected for your part whilst maximising quality. But it is worth noting that a part oriented vertically or horizontally can have a massive time difference. A part laid horizontally would print much quicker than one oriented vertically, where more layers must be built up. A horizontal orientation may not always be suitable for your part, but if it can be printed horizontally, a part with a large height could print considerably quicker this way.

How do materials and processes factor in?

Let’s get straight to the point; if you can print your part using multi-jet fusion, you will get it back much faster than any other service. This, however, is very limiting on material options.

Does your part need to be made from metal? Or would plastic work? Plastic parts generally have a shorter build time than metal. This is due to the complexity of the metal printing processes and the fact that layer thicknesses in plastic printing can be much thicker.

The final point to consider is your features. How complex are they? Do they need to be that complex? Do they need to be that fine/ small? The less complex your part is, the easier and faster it will be to print.

If you need any support with your 3D printed parts, contact Protolabs on +44(0) 1952 683047 or email applicationengineers@protolabs.co.uk to speak to one of our application engineers.